Power quality is a major topic in the field of electrical engineering. A steady and dependable supply of electricity is necessary for daily living as well as the effective operation of several enterprises.

The existence of harmonics is one of the problems that electrical systems frequently encounter. These harmonics can cause several problems, such as higher energy expenses, equipment damage, and decreased power system efficiency.

Many technologies and solutions have been developed to address these problems, and the Static Var Generator (SVG) is one of the major players in this industry.

Static Var Generator Working Principle

To appreciate SVG’s importance, one has to understand how it functions. An electrical system’s harmonic distortion is reduced and power factors are managed by a static variable rate generator. One key component of the efficiency of an electrical system is the power factor, which is a measurement of how well electrical power is turned into worthwhile labour output.

Power Factor Correction

Before we discuss static var generator working principles, let’s take a brief look at the power factor. Power factor correction is the process of raising an electrical system’s power factor. An ideal efficiency of 1 is shown by a power factor of 0 on a standard scale. A power factor of 1 means that all the power supplied to the system is being used effectively, while a power factor less than 1 indicates inefficiency due to factors like inductive or capacitive loads.

In many industrial and commercial applications, loads like motors, transformers, and fluorescent lighting can create inductive loads that lead to a lagging power factor (typically below 1). A lagging power factor results in reactive power, which doesn’t contribute to useful work but still needs to be supplied by the utility. This not only leads to increased energy costs but also reduces the overall efficiency of the electrical system.

Mitigating Harmonic Distortion

Harmonic distortion refers to the presence of unwanted harmonic frequencies in the electrical system. These harmonics are usually integer multiples of the fundamental frequency (e.g., 60 Hz in the United States). Harmonic distortion is primarily caused by non-linear loads such as variable speed drives, rectifiers, and switched-mode power supplies. When harmonics are present, they can lead to a range of problems, including voltage distortion, increased equipment heat, and reduced equipment lifespan.

Now, let’s explore how SVG works to address these issues.

SVG as a Power Factor Correction Device

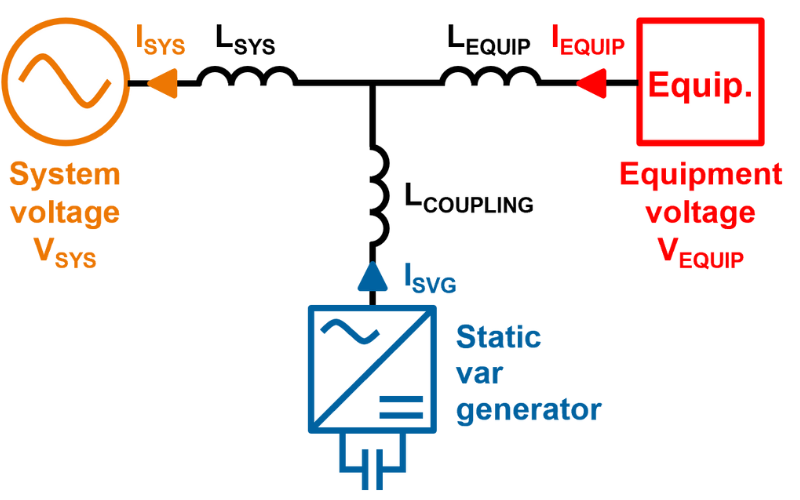

Static var generators are primarily used for power factor correction. They are designed to manage the flow of reactive power in electrical systems, ensuring that it’s supplied or absorbed as needed to maintain a near-unity power factor. This means that SVGs can help reduce the burden of supplying reactive power and improve the overall efficiency of the system.

The key component of an SVG is its power electronic converter, which can either generate or absorb reactive power as required. When the system has a lagging power factor, indicating an excess of reactive power, the SVG absorbs this excess, reducing the lagging power factor towards unity. Conversely, when the system has a leading power factor, indicating a shortage of reactive power, the SVG can generate reactive power to balance the system and maintain a power factor close to 1.

SVG as a Harmonic Filter

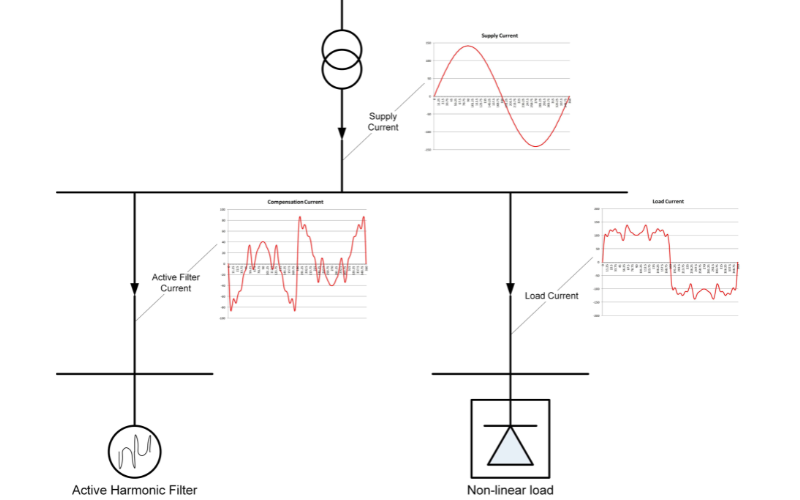

Static var generators can also serve as harmonic filters. In this capacity, they actively mitigate harmonic distortion in the system. The power electronic converter in the SVG can inject compensating current into the system to neutralise the harmonic currents created by non-linear loads.

To achieve this, the SVG continually monitors the system’s harmonic content and produces compensating current of the same amplitude but opposite phase to cancel out the harmonics. This dynamic adjustment helps maintain a clean sinusoidal voltage waveform and ensures that sensitive equipment is protected from the adverse effects of harmonics.

Active Harmonic Filter Benefits

The use of active harmonic filters, of which SVGs are a prime example, offers several notable benefits to electrical systems and the facilities they serve.

Improved Power Quality

The most apparent benefit of active harmonic filters is the enhancement of power quality. By actively mitigating harmonics and correcting power factors, these filters ensure that the electrical supply is stable and clean. This results in a significant reduction in voltage distortion, minimising the risk of equipment malfunctions and improving the overall performance of sensitive devices.

Energy Efficiency

Active harmonic filters can help improve energy efficiency in several ways. By reducing the need for reactive power from the utility, they reduce energy losses. Additionally, they enable equipment to operate more efficiently by maintaining a close-to-unity power factor. This translates into lower energy bills and a reduced environmental footprint.

Equipment Protection

The presence of harmonics can be detrimental to electrical equipment. It can lead to overheating, reduced equipment lifespan, and, in some cases, catastrophic failure. Active harmonic filters play a crucial role in protecting equipment from these harmful effects, ensuring that the facility’s assets remain in good working condition.

Compliance with Standards

Many countries and regions have stringent regulations and standards in place to ensure power quality. Active harmonic filters help facilities meet these requirements by effectively controlling power factor and harmonic distortion. Compliance not only avoids potential penalties but also ensures a reliable and stable power supply.

Cost Savings

While there is an initial cost associated with installing active harmonic filters like SVGs, the long-term cost savings can be substantial. Lower energy bills, reduced maintenance costs, and extended equipment lifespans all contribute to a compelling return on investment.

Typical Applications of Active Harmonic Filters

Active harmonic filters, including SVGs, find applications in a variety of industries and facilities where power quality and efficiency are critical. Some typical applications include:

Manufacturing Facilities

Manufacturing environments often have a multitude of non-linear loads, such as variable frequency drives, welders, and CNC machines. These loads are known for creating harmonics that can lead to power quality issues. Active harmonic filters are employed to ensure stable power quality, minimise equipment downtime, and optimise energy usage.

Data Centres

Data centres are highly sensitive to power quality disturbances. Any disruption in power supply can lead to data loss and system failures. Active harmonic filters are used to safeguard against voltage distortion and ensure the continuous operation of critical IT infrastructure.

Commercial Buildings

In commercial buildings, there are numerous loads, including lighting, HVAC systems, and elevators, that can cause power quality problems. Active harmonic filters help maintain power quality, reduce energy costs, and protect building systems.

Renewable Energy Systems

As renewable energy sources like solar and wind become more prevalent, active harmonic filters play a vital role in ensuring the quality of power generated and fed into the grid. They help regulate the output of these intermittent energy sources, making them more reliable and efficient.

Large Industrial Plants

Large industrial plants with a wide range of machinery and processes often face challenges related to power quality. Active harmonic filters are used to manage power factors and mitigate harmonics, resulting in improved efficiency and equipment protection.

Conclusion

In a world where the electricity demand is ever-increasing, maintaining power quality and efficiency is of paramount importance. The Static Var Generator (SVG) and other active harmonic filters play a pivotal role in achieving these objectives. By actively managing power factors and mitigating harmonic distortion, these devices enhance the reliability of electrical systems, reduce energy costs, and protect sensitive equipment.

The benefits of active harmonic filters extend across various industries, from manufacturing and data centres to commercial buildings and renewable energy systems. They ensure that power quality standards are met, enabling facilities to operate smoothly, reduce operational costs, and contribute to a more sustainable future.

As technology continues to advance, we can expect even more sophisticated and efficient solutions for managing power quality and mitigating harmonics. The SVG and its counterparts are at the forefront of these innovations, making a significant impact on the way we harness and utilise electrical power.